MACHINING

MACHINING

Zinc

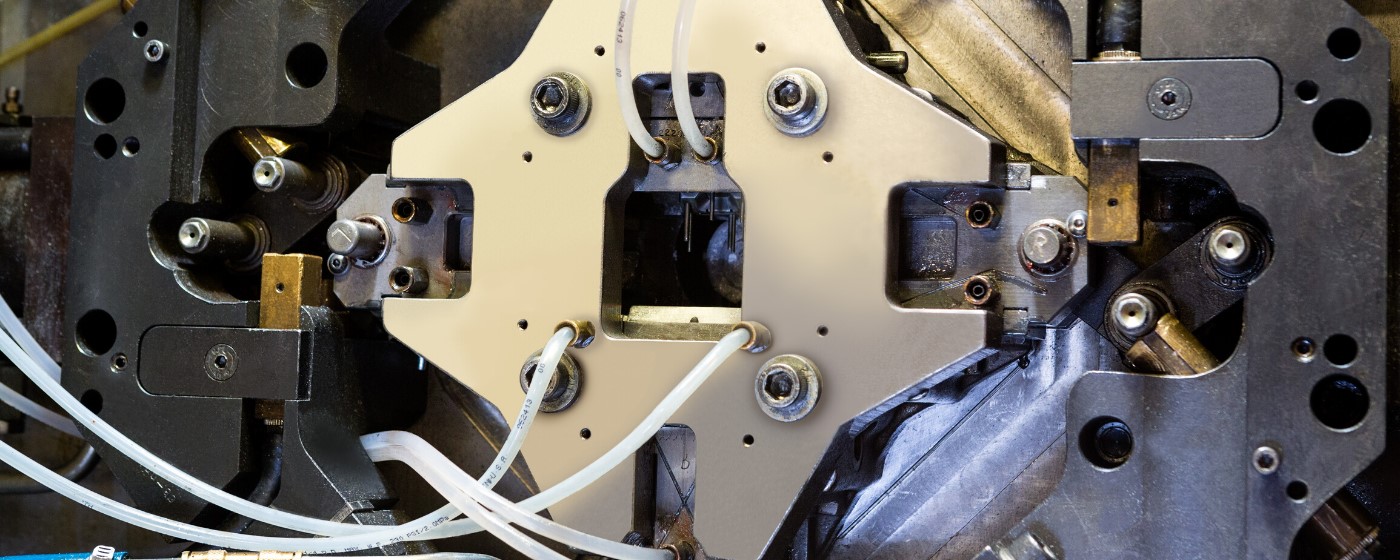

There is usually very little machining required on our precision zinc die castings because of the accuracy we obtain. The machining characteristics of zinc and zinc alloys are excellent and a wide range of machining processes can generally be used.

- Drilling—we can achieve better, more economical drilling under a wide range of operating conditions. To find out how, contact us directly

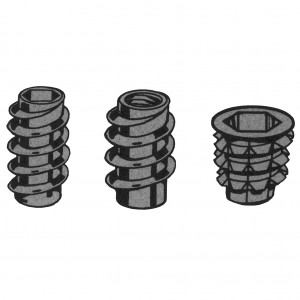

- Tapping—zinc die casting alloys are readily tapped and form excellent thread and hole quality. Threads can be cut or formed with and without lubricants and can be easily tapped using fluteless taps to produce a rolled thread. Fluteless tapping is carried out at higher speeds than cutting taps, and lubrication is essential

- Reaming—our precision zinc die casting process is so precise that holes are cored to the required size for reaming. This means we avoid drilling operations requiring the manufacturing of expensive jigs

Esta capacidad pertenece al expositor: DYNACAST ESPAÑA, S.A.

Otras capacidades del expositor