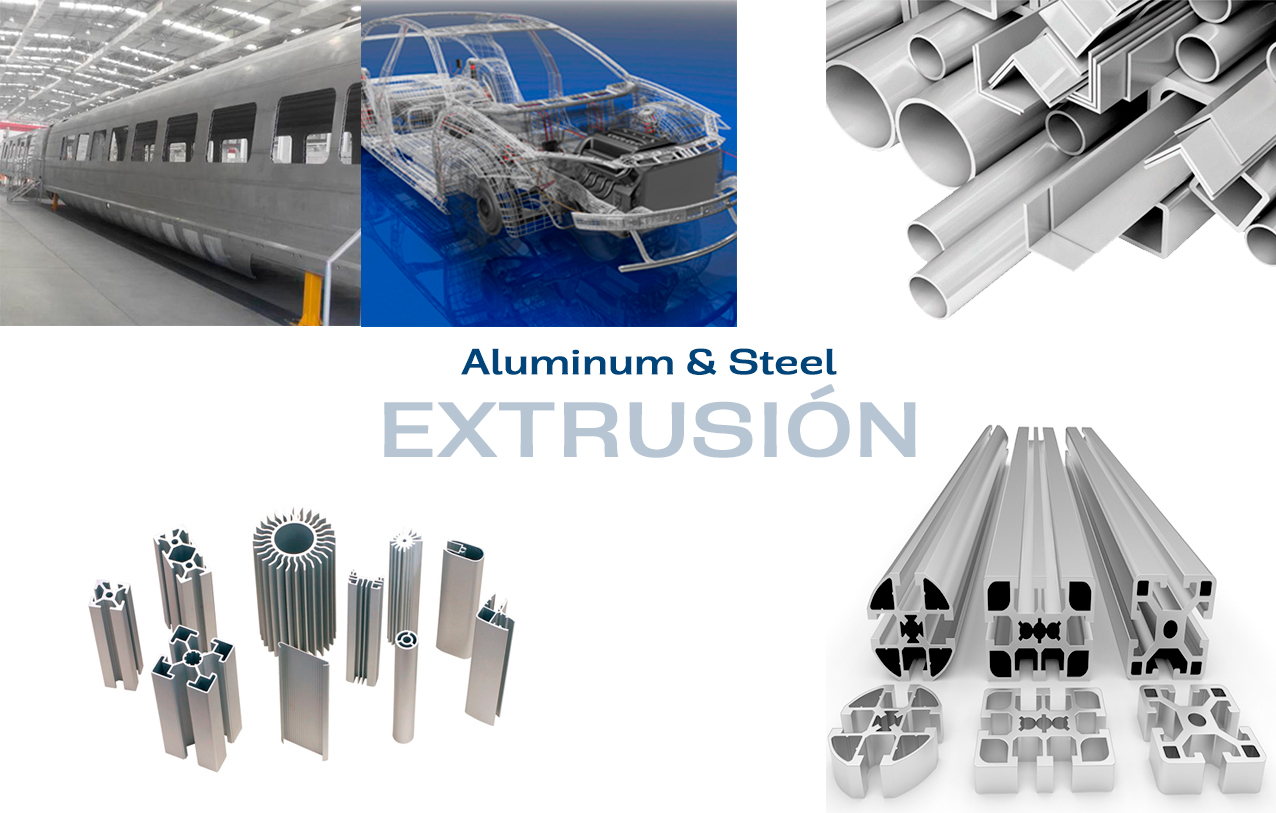

JG Automotive is supplier and manager in the manufacture of components of aluminum and steel extrusion, mainly focused on parts and components in the transport sector: automotive, bus and rail.

The most common products made by extrusion are: Tubes, structural profiles and for frames, rods, rails, joints, plates, seat rails and rings for engines.

THE ADVANTAGES OF ALUMINUM IN THE BODYWORK OF VEHICLES

1- Good resistance to fire and arc of resistance.

2- Fuel savings. Savings of 6% in consumption.

3- High performance in shock absorption. It can absorb resistance between 55-60% compared to steel.

4- Low emission and longer useful life. 1kg Aluminum equals 2 kg of steel.

5- Recyclable. Scrap aluminum reaches a value of about $ 1,550 / Ton. Around 75% of aluminum is recycled in the earth.

6- All the weight of the vehicle is lighter, reducing in a 10% the weight of a steel body.

The benefits that aluminum achieves with respect to steel are mainly: the simplicity of the structure, lower cost, lighter, easy to assemble and easy to repair.